Maintenance procedures for plastic molds

Molds, like any other tools, begin to wear over time, and maintaining one is an investment in precision, so the best quality parts have been produced with quality molds.

Maintenance is a matter of attention to detail in order to prevent or identify any potential problems before they become critical. This is easily achieved by keeping a work log of all maintenance issues as they appear, as well as performing periodic maintenance on the tool as it is run in production.

This guideline describes the proper methods for maintaining molds and is intended to provide customers with guidelines. Customers are responsible for setting a schedule for proper maintenance and following it.

Four factors determine the degree and frequency of maintenance:

Steel:

Aluminum or soft tools will last only a short period of time as compared to tools made from conventional tool steel. Hardened steel molds will last longer than conventional mold steel.

Complexity:

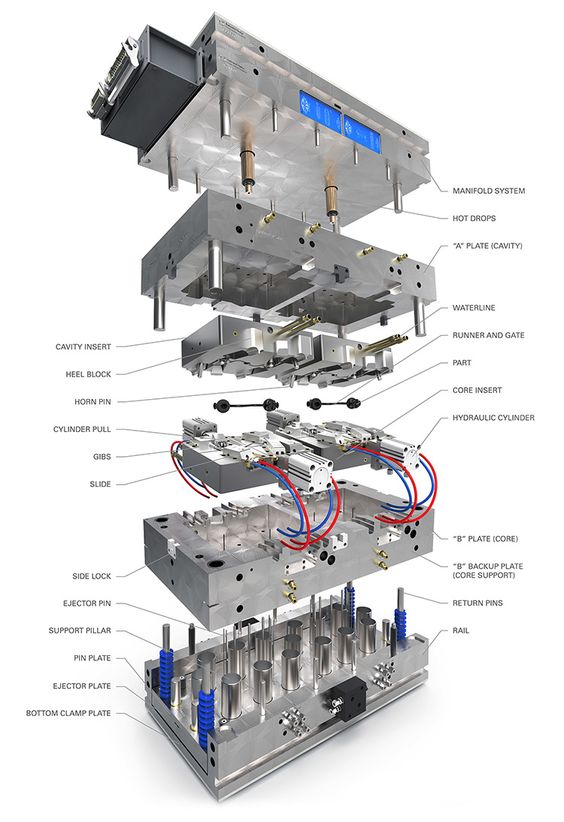

Molds that require very high levels of precision and intricate mechanisms will require more maintenance than simple two-plate tools that make parts that are not very precise, since the tools will need to be replaced more often than two-plate tools.

Other factors which contribute to maintenance of the plastic mold include sliding and lifting mechanisms, internal cores, hydraulic and mechanical systems, hot runners, complex ejector systems or mechanisms with small, therefore weak, components.

Plastic material:

High melting point materials wear out molds faster than low melting point materials. A higher melting point will expose the metals to more heat and increase wear. Filled materials are abrasive since the fillers are not liquid.

In the long run, these composites, such as fiberglass and mineral fillers (usually mica), etc., because they are abrasive to metal, will tend to wash the steel away.

Abuse:

Excessive clamping pressure, high injection pressures, frequent closing and opening of the mold, not lubricating the necessary components, multiple ejection, closing the mold before the part passes out, and so forth are a sure way to increase the maintenance.

It is also possible to abuse a mold at the workplace as a result of a messy work area, dust, and dirt in the shop, machines covered in grease, and absorbent on the floor. This creates an atmosphere of accelerated deterioration of the mold.

Acidic vapors, such as those present in an area of molding adjacent to an electroplating operation, will corrode the steel. High uncontrolled humidity and salt waters can also contribute to corrosion. Frequent wind and dust cause premature deterioration of the steel over time.

Utilizing non-treated coolant in the tool can result in the development of a scale buildup in the water lines. The scale can be detected if the differential of temperatures and pressure between the inlet and outlet of the cooling circuit is elevated.

This scaling negatively affects the heat transfer capability of the tool and leads to decreased process capability and part quality, even with the tool steel in perfect condition. Part quality may be severely affected if the cooling circuits are clogged or constrict.

Environmental abuse: What are the solutions?

1.Ensure that your equipment and tools are well maintained.

2.In cooling systems, use soft or treated water.

3.When the tool is removed from the machine, blow it out or drain its contents.

4.Mold should not be exposed to the outside environment.

5.Obtain filtered, positively pressurized air from outside and circulate it inside.

Maintenance step instructions.

stage 1: Routine maintenance occurs every time a mold is pulled or reintroduced into production. Stage 2: The cycle count for Inspection & Maintenance is 25,000 cycles or 10 shifts.

Stage 3: 100,000 cycles for General Maintenance or every 10 productions runs.

Stage 4: 250,000 cycles or half the anticipated lifetime volume to be addressed as soon as possible for Major Maintenance.

Stage 1 : Routine Simple Preventative Maintenance

Routine Simple Preventative Maintenance or SPM, is a preventive maintenance procedure that should be followed every time a mold is taken out of production. The mold shall be heated before it is removed from the press to evaporate all surface condensation.

Keep the mold high temperature, clean with shop safety solvent any residual dirt or grime, the ejector system should move forward fully, then spray with approved rust preventives then retract the ejector system fully and close the mold.

If you are going to protect lenses and highly polished surfaces, you need to follow specific instructions regarding how to do so.

Water lines must be drained and blasted free of all residual water to prevent the build-up of rust. If there is moisture trapped within mold, it must be blown out completely.

Make sure that all bolts, sliders, lifters, core and cavity inserts, etc. are secure.

The last shot should be stored with the mold as an example of how the quality of this run is typical. Simple Preventative Maintenance (SPM), should be done whenever tools are retrieved from storage:

Open the mold. Remove the mold anti-rust preservative using the appropriate solvent and a lint-free pad, followed by the first shot of the item, and then the next shot as indicated. Running the parts immediately is NOT a good practice and it can cause contamination.

Stage 2 :Visual Inspection Maintenance

The lead operator or a toolmaker should perform this inspection at the end of a production run. The mold should be inspected by the use of the checklist and visual inspection methods, as well as noted any minor repair requirements in the form of a note so that it can be used in the General Maintenance procedure.

In that event, repair notes or future touchup reminders are kept in the mold history log for future reference.

Any deficiencies or blockages should be noted and corrected. A sample of the blocked cavity should be retained by the mold maker so they can be repaired.

After the molding process, the mold should be cleaned with a safe solvent so as to remove the varnish and buildup.

In four clockwise directions around the cavity face, the vent depth should be checked for the blockage due to the relics of injected material.

The form should note the type of work to be performed during the General Maintenance procedure.

Damaged, scratched or bent ejector pins should be noted and the injection molding should be discontinued and the pins should be replaced.

Stage 3: General Maintenance(GM)

The work should only be performed by competently trained technicians in the tool room.

A cleaning agent is sprayed into the cavity and wiped clean with cotton balls only. Caution: Highly polished surfaces should not be cleaned with brushes or rags. They should be cleaned with only uncontaminated facial tissues or cotton balls.

Be cautious when blowing out a polished cavity as rust or dust may get into the air lines and scratch the polished surface. Do not touch the surface with fingers.

The components should be inspected to determine if undue wear has occurred, and then a choice is made whether to repair, substitute, or continue to use the failed component.

All rough areas outside of the cavity detailing area should be smoothed out. Any area inside the cavity detail area with dings, dents, or other evidence of abuse needs to be analyzed carefully to determine if it requires replacement or repair.

If the tool needs lubrication, then lubrication is to be applied to the moving parts, and to be applied carefully to them. Vents need to be double examined for depth, width and land, as well as for dimensional compliance with the drawings.

These data must be included on the check-list and a determination made to repair if necessary.

They should also be evaluated for corrosion and damage to the vents (better venting may be required). Check the integrity of the "O" rings, seals and gaskets.

All channel layout lines should have their flow capacity tested and recertified. If the water lines have accumulated scale and are restricted, they should thoroughly clean them using a descaling agent.

The alignment of the ejector system should be checked. The ejector pin holes should be redrilled and enlarged if they have become deformed, and the existing pins should be replaced with larger ones if necessary.

Broken return springs, retexturing or replating after the substance erodes the mold surface, replacement of the gate inserts, new runner blocks, and other replacement measures should be explored and determined, and springs should be substituted after 45,000 cycles.

Stage 4: Main Maintenance

This maintenance should be carried out by a skilled tool and die specialist. It should be performed when the maintenance intervals are complete, or the tool is damaged or worn beyond its design life. Data logging here is quite important.

Before tooling is maintained, four complete shots should be delivered, including parts(including failed part), sprues, gates, and runners for study.

During initial mold qualification, two shots should be taken from the mold. This gives a clear idea of what the mold was capable of producing when it was new and fully functional. The second set of shot should be the part that was produced the most recently.

The comparison of the before and after shots will demonstrate the wear and abuse the tool has experienced.

If previously certified spare components are not available, all components that are determined to be necessary should be removed from the machine and new components should be constructed and installed according to the original designs.

Worn guide pins, guide pin bushings, sliders, lifters, moveable core and other moving components should be inspected and replaced or repaired as needed.

Plates and mold cavities' surfaces should be checked to make sure that they are parallel and if necessary, ground flat.

Mold cavity surface should be cleaned and polished according to the original surface specifications. Minor surface imperfections, such as dings, gouges, and cracks, should be dealt with until the surface is compliant with the original print.

Re-qualification should be performed on any component that does not meet the original specifications on the part print, and must meet the manufacturer's requirements.

If necessary, all plating needs to be removed and the components replated where necessary. All surface treatments that are purely cosmetic should be removed and retreated to the level of original purpose of it, and whether this is corrosion resistance, hardness, lubricity, or the like.

All moving components should be checked and adjusted if necessary. The return springs should be replaced with new ones to prevent excessive wear and tear.

During regular cleaning of water lines, descaling agents should be used in order to eliminate scale build up. The internal gaskets, external gaskets as well as o rings, and seals were to be replaced.

For tools requiring a high degree of production, the mold should be dismantled, the cavities should be removed and the material should be stressed relieved. The entire mold/cavity set should be inspected and requalified as though it were a new cavity.

The mold base is to be inspected for cracks, work hardening, corrosion, etc. If the mold base was plated or painted for corrosion resistance, the coating is to be stripped, the base cleaned and the coating reapplied. The mold's ID is to be redone indicating the tool was rebuilt.

The cavity surfaces are to be examined for wear or erosion of plating or texturing. By determining if this is necessary, the cavity surfaces are to be stripped, replated, or if needed, the existing textures will be removed and replaced with new ones.

Provide a rigid impact resistant material so as to protect the exposed areas like the cavity and the core. Such a material can be a sheet of plywood or rigid plastic.

Accidentally dropped tools or parts can end up causing extensive damage as a result of ending up on top of a cavity or core insert.

Please contact us with mold@hlmold.work for more information about mold making and maitenance.

What is daylight in injection molding machine

Advanced CNC Tecnnology In HL Mold

Overmolding vs Insert Molding

Contact: HLM

Phone: 13332689118

Tel: 86-13332689118

Email: lily@hlmold.com

Add: Building 43,58 Wei Road,Qishi Town,Dongguan city,Guangdong province, China

We chat